what is Liquid Packaging Board?

Liquid Packaging Board (LPB) 2025 is traditionally associated with beverage packaging, including for milk, juice boxes and other dairy products, but its applications extend beyond just liquids, encompassing a broad range of uses due to its strength, barrier properties, and versatility.

Features of Liquid Packaging Board

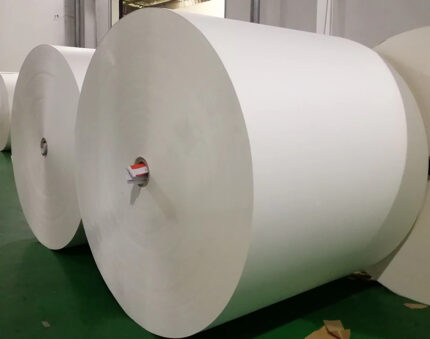

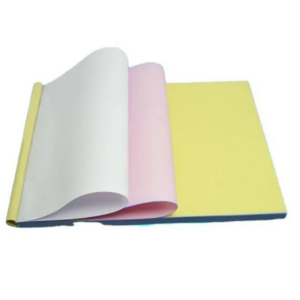

The Liquid Packaging is composed of four layers: mechanical, chemical, and broad-leaf pulps as well as natural color pulps. The bottom layer also contains natural color pulps. The coating layer is made up of calcium carbonate, China clay, adhesive, water retaining agent, and water repellent agent. The surface layer contains chemical broadleaf pulp and chemical coniferous pulp.

paper packaging for liquids

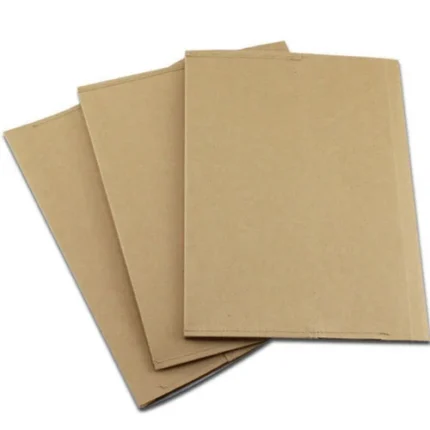

The kraft back liquid-wrapped base paper of the current invention has the following benefits: it is inexpensive, using less chemicals means less pollution in the environment; it is visually appealing and has good printing and decoration capabilities; it satisfies food requirements and is safe for human consumption.

liquid paperboard

- 1-6 color with Offset/Flexo Print

- Waterproof, Excellent brightness and smoothness, Good runnability

- 100% food grade FDA

- ISO 9001:2000, ISO14001:2004, SGS, FSC, FDA are all available

Application of Liquid Package Board

Applications for Liquid Board Packaging are numerous and include the packaging of milk or juice, as well as food packaging such as trays, hamburger boxes, chicken boxes, and other food packaging boxes. In addition, Liquid Packaging Board can be functionally treated with grease resistance and other materials like greaseproof paper and aluminum foil for lamination.

Specification of Liquid Package Board

(Email us for more information of Liquid Packaging Board)

| PRODUCT NAME | Liquid Packaging Board | |||||||

| Liquid Packaging Board | 190g | 200g | 215g | 230g | 280g | 300g | 335g | 340g |

liquid packaging board manufacturers

Choose Nusa Paper Group in 2025 for your Liquid Package Board needs and experience exceptional quality, competitive pricing, and outstanding customer service. Contact us today to learn more about our products and how we can support your packaging goals!

Reviews

There are no reviews yet.